TL;DR

Grading decisions made at the dock determine everything that happens next—costing, yield planning, production sequencing, product allocation, and even revenue forecasting.

When offload weights and grades are captured manually, operations lose visibility. But when grading is tied directly to offload data inside inecta Food ERP, production teams get precise, real-time information that drives better decisions, higher profitability, and full traceability from vessel to finished product.

Grading Isn’t Just a Dockside Task—It’s a Production Driver

Every seafood processor uses grading—by size, quality, species, or condition—but few understand how deeply it impacts production accuracy.

The grade assigned at offload determines:

-

Which production line the product goes to

-

Expected yield and trimming labor

-

Cost of goods sold

-

Inventory classification

-

Margin on every pound

-

Customer allocation and pricing

-

Processing schedules and throughput

When grading is done manually or disconnected from offload data, the entire downstream workflow becomes guesswork.

When grading and offload data are captured together—digitally, accurately, and in real time—everything syncs.

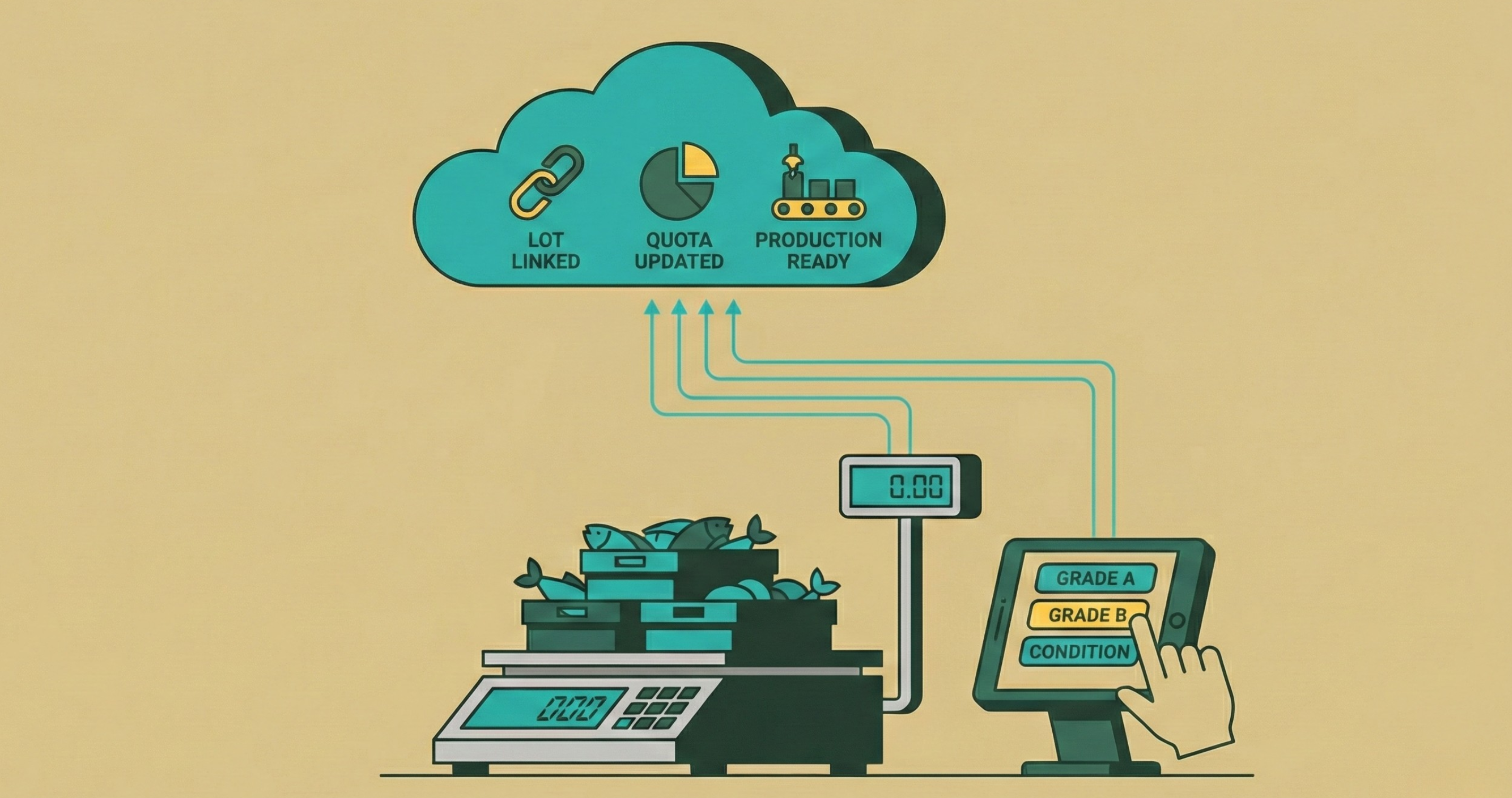

Unified Offload + Grade Capture: The First Step to Accurate Production

Most seafood operations still treat offload and grading as two separate moments. But in reality, they must be recorded together.

With inecta Food ERP:

-

Weights flow directly from dockside digital scales

-

Crew or dock staff select grade classifications on a tablet or terminal

-

Species, grade, and condition link instantly to the correct lot

-

Quota profiles update immediately

-

Graded product becomes available for production in real time

This eliminates the classic pain points:

-

Missing grade sheets

-

Mis-entered grade codes

-

Over/understated yields

-

Incorrect product routing

The moment offload is confirmed, production has accurate graded inventory.

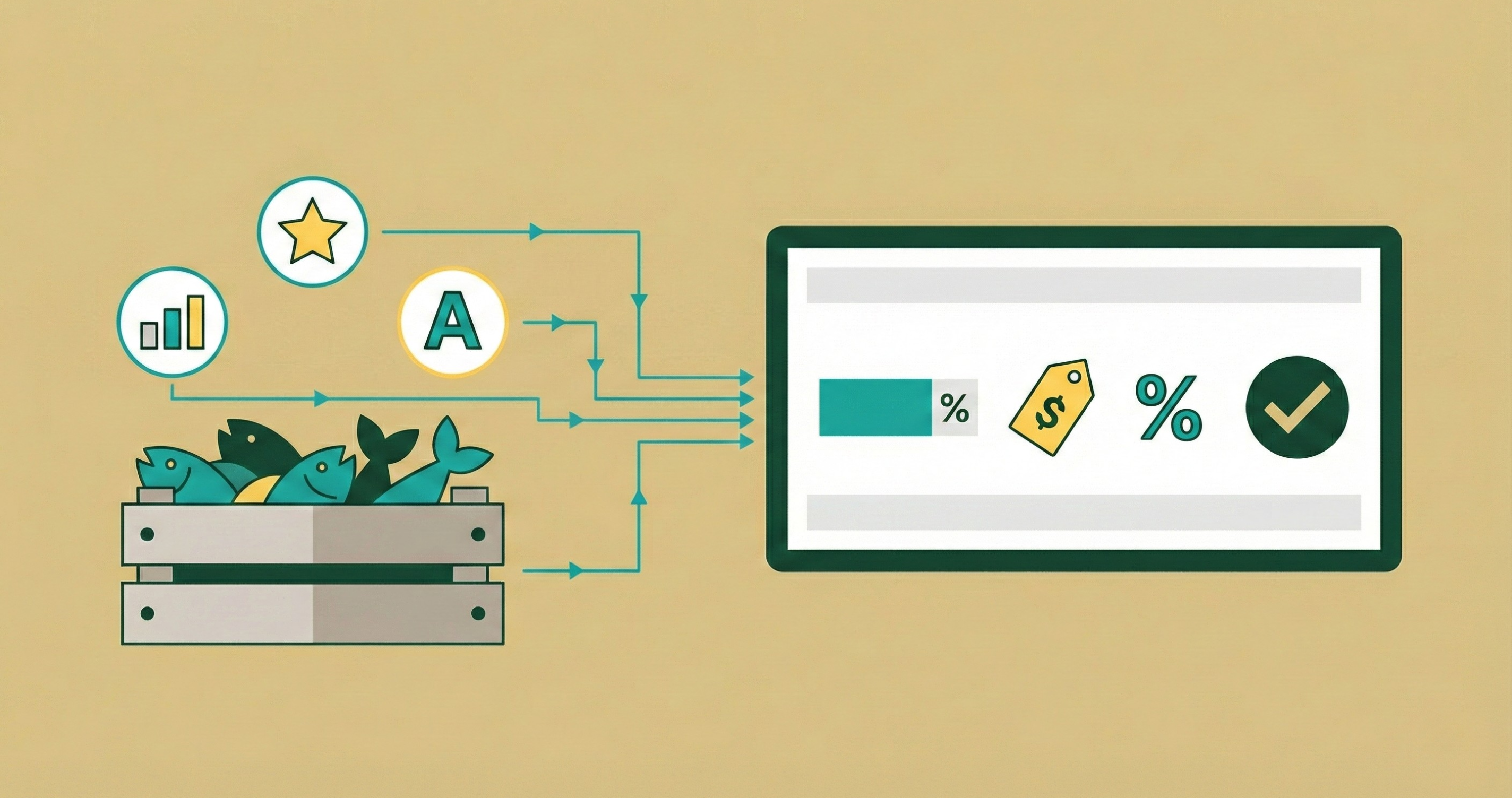

Accurate Grades = Accurate Yields, Costing, and Pricing

Production accuracy lives or dies on the quality of grading data.

Yield Projection

inecta uses grade data to forecast trimming yields, recovery percentages, and production output.

If grade is incorrect → yield is incorrect → cost is incorrect → price is incorrect.

Costing & Margin

Different grades carry different:

-

Labor costs

-

Yield expectations

-

Market prices

-

Production routes

inecta ties all of these back to the original offload grade, giving fleets a real financial picture of each landing or purchase.

Real-Time Inventory Accuracy

Before product ever reaches the line, inventory is:

-

Classified

-

Costed

-

Quota-validated

-

Allocated correctly

-

Ready for scheduling

All from grade-integrated offload data.

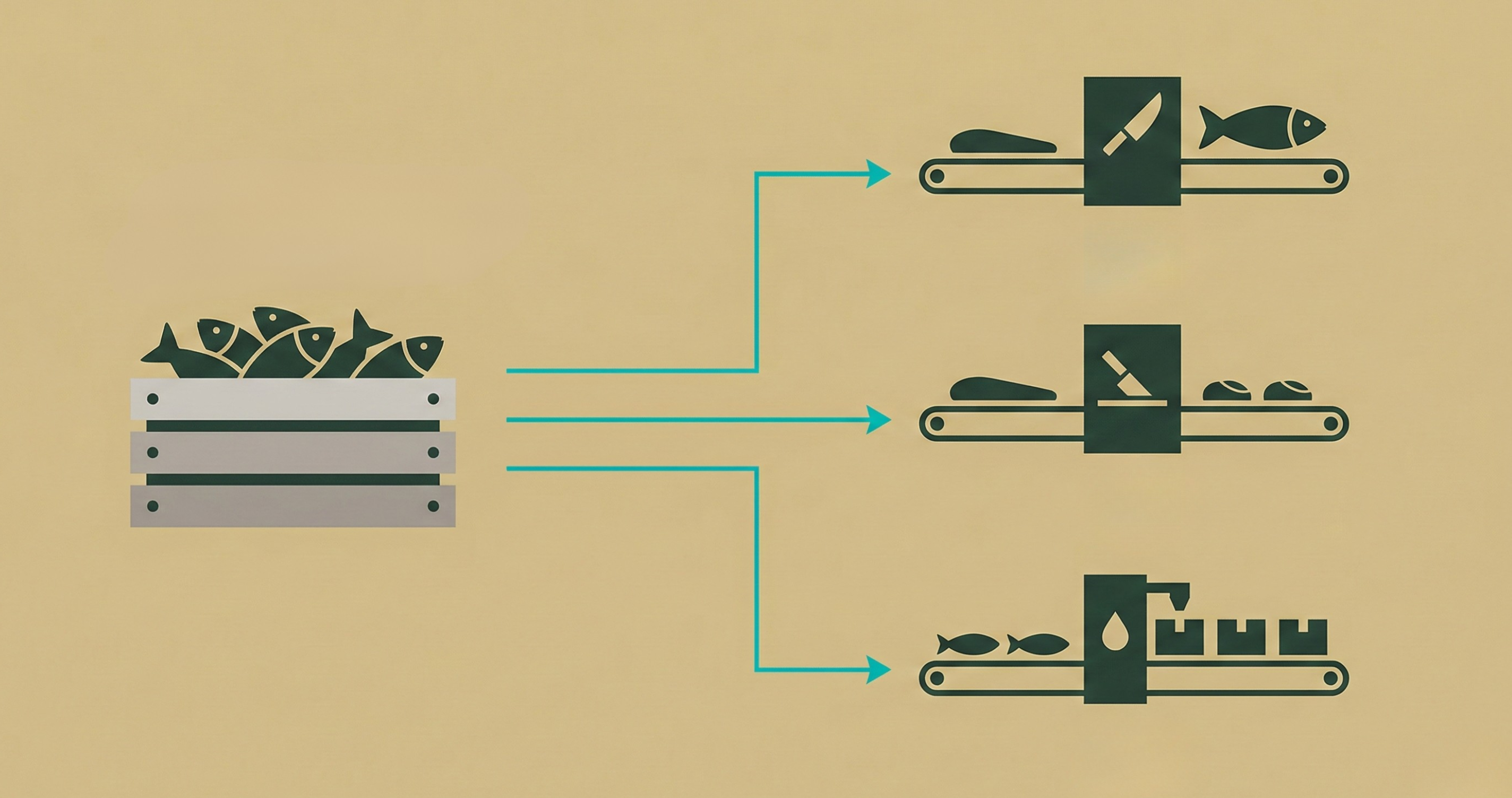

Production Flow Runs on Grade Data—Not Estimates

Once the product is graded, the plant needs to know:

-

Which line to run it on

-

Which equipment settings to use

-

How to batch it

-

Whether it goes to filleting, trimming, freezing, or packaging

-

Whether it’s for export or domestic

-

Which customer specs it meets

inecta automates these decisions by linking grade directly to production routing rules.

Examples:

-

Grade A → premium loin line

-

Grade B → trimming and portioning

-

Grade C → mince or value-added processing

No misroutes.

No delays.

No wasted production time.

Grade Data Improves Sales Allocation, Customer Fulfillment, and Profitability

Sales teams need accurate grades to:

-

Match product to customer specs

-

Quote accurate prices

-

Allocate premium grades to premium buyers

-

Avoid overpromising inventory

When offload → grade → inventory happens automatically inside ERP:

-

Every team works off the same single source of truth

-

Customer expectations are always aligned

-

The plant knows what’s coming and where it’s going

-

Finance gets accurate COGS

-

Sales gets accurate availability

-

Everyone wins

FAQ

1. Why is grading data so important in seafood production?

Because it determines yields, pricing, costing, routing, and customer allocation. It is the foundation of production accuracy.

2. How does inecta capture grades during offload?

Dockside digital scales and grading terminals send species/grade/weight directly into ERP in real time.

3. Does grading affect quota and compliance?

Yes—correct grading ensures accurate reporting, consistent lot definitions, and clean reconciliation with regulatory systems.

4. Can grading drive automated production routing?

Absolutely. inecta uses grade rules to automatically direct product into the correct lines or processing workflows.

When grading data is integrated with offload and production, accuracy becomes automatic—and profitability follows.

See how inecta Food ERP brings this ecosystem together from the moment product hits the dock.

Explore inecta Seafood ERP: https://www.inecta.com/seafood-erp

Free Valuable Resource!

3 simple steps to find your Food ERP

Free Valuable Resource!

3 simple steps to find your Food ERP

*We will never sell your information. Keeping your data and privacy secure is our highest concern.