What is a Corrective Action Plan?

Corrective action is a crucial component of any food safety management system, including Hazard Analysis and Critical Control Points (HACCP). A Corrective Action Plan (CAP) is a written document that outlines the steps that a food business will take to address any deviations or non-conformities identified during the implementation of their HACCP plan.

.png?width=6974&height=2151&name=Untitled%20design%20(6).png)

HACCP is a food safety management system that aims to prevent, eliminate, or reduce food safety hazards to an acceptable level. It involves identifying critical control points (CCPs) in the production process where hazards can be controlled or eliminated. These CCPs are monitored regularly to ensure that the process is operating within specified limits. If a deviation occurs, a corrective action must be taken to bring the process back to control.

A Corrective Action Plan is an essential element of the HACCP system, as it ensures that any deviations from the HACCP plan are addressed quickly and effectively to prevent the risk of a food safety incident. The CAP should be developed as part of the HACCP plan and should be specific to each CCP. The CAP should be reviewed and updated regularly to ensure that it remains effective.

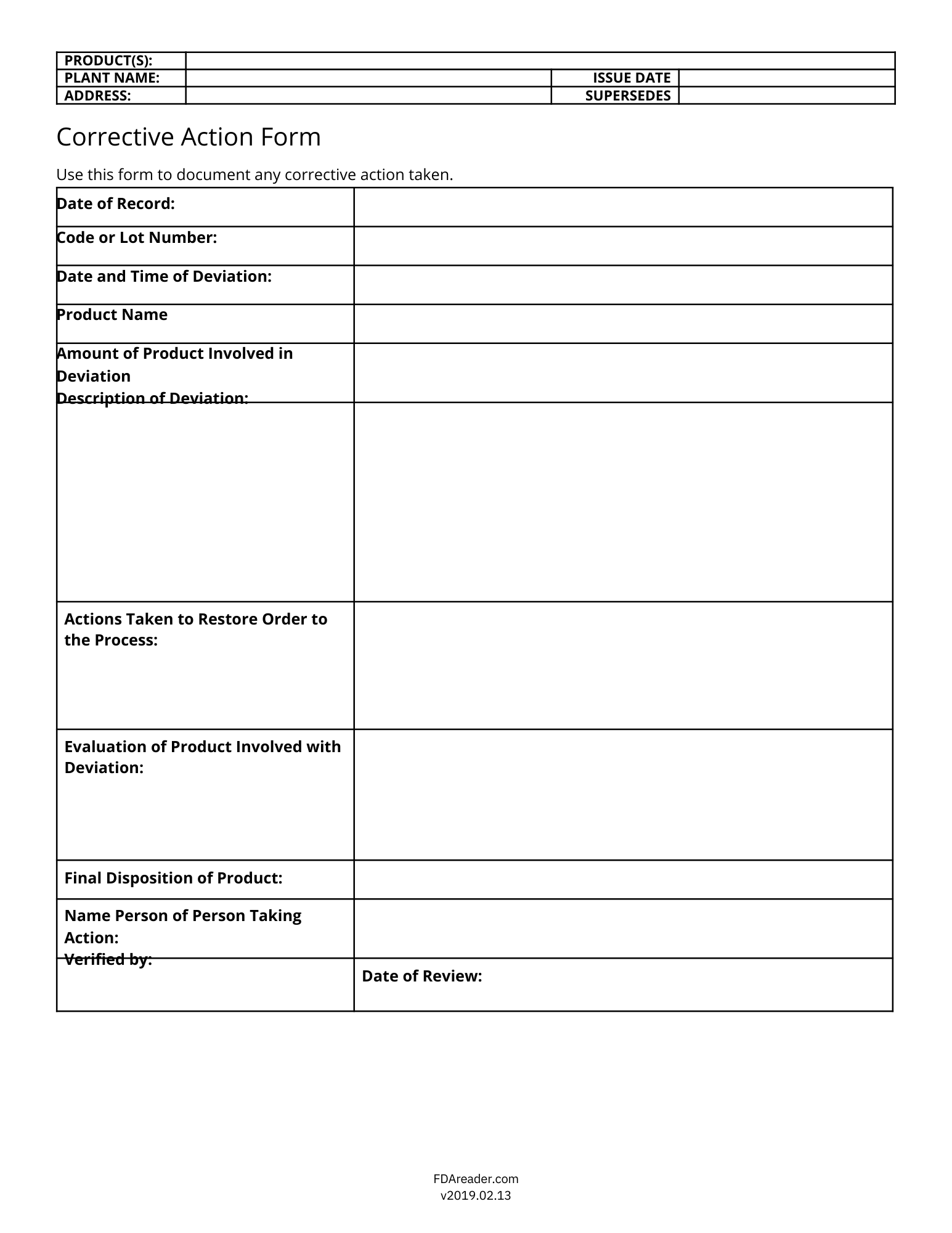

The Corrective Action Plan should include the following elements:

-

Description of the non-conformance or deviation: The CAP should clearly describe the non-conformance or deviation that has been identified. This description should include the type of deviation, the CCP involved, the date and time of the deviation, and any other relevant information.

-

Immediate corrective action: The CAP should outline the immediate corrective action that will be taken to address the deviation. This could include stopping production, reworking the product, or disposing of the product.

-

Investigation and root cause analysis: The CAP should include an investigation into the cause of the deviation. This investigation should include a root cause analysis to identify the underlying cause of the deviation. This analysis will help to identify any underlying system or process issues that need to be addressed to prevent similar deviations from occurring in the future.

-

Preventive action: The CAP should outline any preventive action that will be taken to prevent the deviation from occurring again. This could include updating procedures, training staff, or making changes to the production process.

-

Verification: The CAP should include a verification process to ensure that the corrective and preventive actions have been effective in addressing the deviation. This could include monitoring the CCP to ensure that it remains within specified limits, conducting testing of the product, or reviewing records to ensure that the corrective and preventive actions have been implemented correctly.

-

Recordkeeping: The CAP should include a recordkeeping process to ensure that all actions taken are documented. This documentation should include the date and time of the deviation, the corrective and preventive actions taken, and any verification activities that were conducted.

Managing food safety risks is essential to protecting consumers and maintaining the reputation of food businesses. The Corrective Action Plan is a critical component of the HACCP system, as it ensures that any deviations from the HACCP plan are addressed promptly and effectively. The CAP provides a framework for addressing deviations and preventing similar incidents from occurring in the future. Effective CAPs require commitment and dedication from all levels of the organization, including management, employees, and stakeholders.

In conclusion, the Corrective Action Plan is an essential element of any HACCP plan. It provides a framework for addressing non-conformities and deviations, preventing food safety incidents, and continuously improving the food safety management system. A well-designed and implemented CAP is crucial to managing food safety risks and protecting consumers. Food businesses must invest in developing and implementing effective CAPs to ensure that they are meeting their food safety obligations and protecting their consumers.

Why do food companies need a corrective action plan?

In the food industry, ensuring the safety of the products is of utmost importance. Food businesses must identify potential food safety hazards, manage food safety risks, and take corrective actions to prevent the occurrence of hazards. A Corrective Action Plan (CAP) is a crucial element of a food business's Hazard Analysis and Critical Control Points (HACCP) system, which helps companies ensure the safety of their products and protect consumers.

A CAP is a written document that outlines the steps that a food business will take to address any deviations or non-conformities identified during the implementation of their HACCP plan. It serves as a roadmap to ensure that corrective actions are taken in a timely and effective manner to prevent the recurrence of hazards.

One of the primary reasons food companies need a corrective action plan is to manage food safety risks. By identifying and addressing potential hazards, food businesses can prevent the occurrence of foodborne illnesses and protect consumers. A CAP helps businesses identify critical control points (CCPs) in their production process, where hazards can be controlled or eliminated. Once CCPs are identified, they can be monitored regularly to ensure that the process is operating within specified limits. If a deviation occurs, a corrective action must be taken to bring the process back to control.

A CAP also helps food businesses comply with regulations and industry standards. Many regulatory bodies, such as the Food and Drug Administration (FDA), require food businesses to have a HACCP plan in place. A CAP is an integral part of the HACCP plan and demonstrates a food business's commitment to food safety. Additionally, many industry standards, such as the Global Food Safety Initiative (GFSI), require businesses to have an effective CAP in place to ensure food safety.

Corrective actions are essential in preventing food safety hazards. In the event of a deviation, a CAP helps businesses take immediate corrective action to address the deviation. Immediate corrective actions could include stopping production, reworking the product, or disposing of the product. By taking immediate corrective action, food businesses can prevent the occurrence of food safety hazards and minimize the risk to consumers.

A CAP also helps food businesses investigate the cause of the deviation and identify the root cause. This investigation includes a root cause analysis, which helps identify the underlying cause of the deviation. This analysis helps businesses identify any underlying system or process issues that need to be addressed to prevent similar deviations from occurring in the future. By addressing the root cause, businesses can prevent the recurrence of deviations and reduce the risk of food safety hazards.

Preventive actions are also a crucial component of a CAP. A CAP should outline any preventive action that will be taken to prevent the deviation from occurring again. Preventive actions could include updating procedures, training staff, or making changes to the production process. By taking preventive actions, businesses can prevent the occurrence of deviations and reduce the risk of food safety hazards.

Verification is also an essential element of a CAP. A CAP should include a verification process to ensure that the corrective and preventive actions have been effective in addressing the deviation. This could include monitoring the CCP to ensure that it remains within specified limits, conducting testing of the product, or reviewing records to ensure that the corrective and preventive actions have been implemented correctly. Verification helps ensure that the CAP is effective and that deviations are addressed in a timely and effective manner.

Recordkeeping is also crucial when it comes to a CAP. A CAP should include a recordkeeping process to ensure that all actions taken are documented. This documentation should include the date and time of the deviation, the corrective and preventive actions taken, and any verification activities that were conducted. Recordkeeping ensures that food businesses have a record of all deviations and corrective actions taken, which can be used to demonstrate compliance with regulations and industry standards.

How to create a Corrective Action Plan

A Corrective Action Plan (CAP) is a critical element of any food business's Hazard Analysis and Critical Control Points (HACCP) system. A CAP is a written document that outlines the steps that a food business will take to address any deviations or non-conformities identified during the implementation of their HACCP plan. A well-designed CAP can prevent food safety hazards, protect consumers from foodborne illnesses, and demonstrate a food business's commitment to food safety. In this article, we will discuss how to create a corrective action plan and the steps needed.

Step 1: Identify the Problem

The first step in creating a CAP is to identify the problem. This can be done through monitoring and verification activities that are a part of the HACCP system. The problem could be a deviation from critical limits or a non-conformance with the HACCP plan.

Step 2: Define the Problem

Once the problem has been identified, the next step is to define the problem. This involves determining the scope of the problem, the potential impact on food safety, and the root cause of the problem.

Step 3: Develop a Plan

Once the problem has been defined, the next step is to develop a plan to address the problem. The plan should include corrective actions and preventive actions. Corrective actions are the steps that will be taken to address the immediate problem, while preventive actions are steps that can be taken to prevent the problem from occurring again in the future.

Step 4: Implement the Plan

Once the plan has been developed, the next step is to implement the plan. This involves taking the corrective and preventive actions identified in the plan. It is important to ensure that all actions are completed as planned.

Step 5: Verify the Plan

Once the plan has been implemented, the next step is to verify the effectiveness of the plan. This involves monitoring and verification activities to ensure that the problem has been addressed and that the corrective and preventive actions have been effective.

Step 6: Document the Plan

All steps in the CAP process should be documented. This includes the identification of the problem, the definition of the problem, the development of the plan, the implementation of the plan, and the verification of the plan. Documentation should include the date and time of the problem, the corrective and preventive actions taken, and any monitoring and verification activities that were conducted.

Step 7: Review and Revise the Plan

The final step in the CAP process is to review and revise the plan. This involves reviewing the plan on a regular basis to ensure that it is still effective and up to date. If necessary, the plan should be revised to reflect changes in the production process or new information on food safety hazards.

In conclusion, a Corrective Action Plan (CAP) is an important component of a HACCP system. It outlines the steps that a food business will take to address any deviations or non-conformities identified during the implementation of their HACCP plan. By following the steps outlined above, food businesses can create an effective CAP that will help prevent food safety hazards and protect consumers from foodborne illnesses.

Food Safety Plan & HACCP Templates |

||

|

Hazard Analysis |

Process Preventive Controls |

Corrective Action Form |

|

Receiving Log |

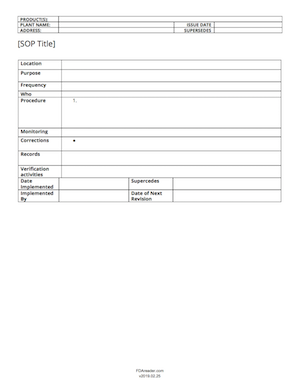

SOP Template |

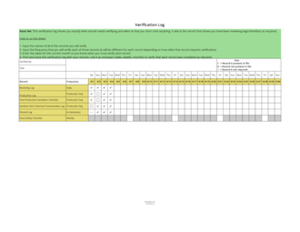

Verification Log

|

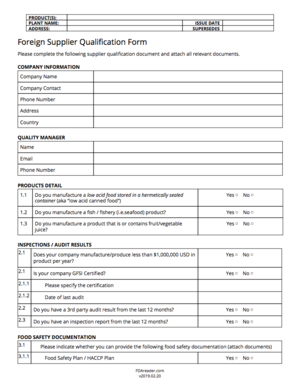

Supplier Verification Templates |

||

|

Supplier Qualification Form

|

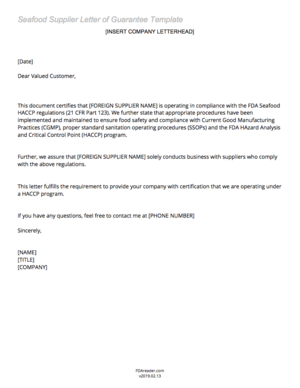

Seafood Supplier Letter of Guarantee Request

|

Letter of Specification to Carrier Partners

|

Sanitation Templates |

||

|

ph Calibration Log

|

Pest Sighting Log

|

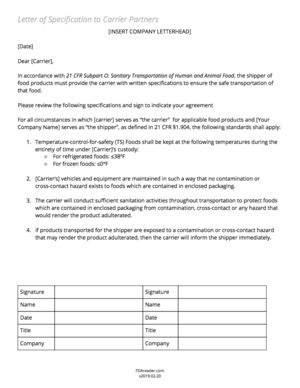

Sanitizer Concentration Log

|

Food Defense Templates |

||

|

Vulnerability Assessment

|

|

|

What is an example of a weak corrective action plan?

A Corrective Action Plan (CAP) is an important part of a Hazard Analysis and Critical Control Points (HACCP) system. It outlines the steps that will be taken to correct any deviations or non-conformities that are identified during the implementation of the HACCP plan. However, not all CAPs are created equal. Here is an example of a weak corrective action plan:

Let's say that a food business has identified a critical control point (CCP) where a critical limit is not being met. The critical limit relates to the temperature of food during the storage process. The HACCP plan has identified a critical limit of 5°C to prevent the growth of harmful bacteria. However, the temperature of the food in the storage area has been measured at 8°C, indicating a deviation from the critical limit.

A weak corrective action plan in this situation would be to simply adjust the temperature of the storage area to meet the critical limit. While this would address the immediate issue, it does not address the root cause of the problem. For example, the cause of the deviation could be a malfunctioning refrigerator or inadequate employee food safety knowledge.

To create a strong corrective action plan, the root cause of the deviation needs to be identified and addressed. This could involve training employees on proper food storage procedures or repairing the malfunctioning refrigerator. Additionally, the corrective action plan should include monitoring and verification activities to ensure that the corrective actions have been effective and that the critical limit is being met consistently.

Another weakness in the example above is the lack of involvement from a food safety supervisor. It is important for a food safety supervisor to be involved in the development and implementation of the corrective action plan to ensure that it meets industry standards and regulations.

In conclusion, a weak corrective action plan is one that simply addresses the immediate problem without identifying and addressing the root cause. A strong corrective action plan involves identifying the root cause of the problem and developing a plan that includes monitoring and verification activities, as well as involvement from a food safety supervisor. By taking the time to develop a strong corrective action plan, food businesses can prevent food safety hazards and protect consumers from foodborne illnesses.

Corrective Action Plan Example

.jpg?width=1313&height=875&name=Untitled%20design%20(19).jpg)

A Corrective Action Plan (CAP) is an essential tool for addressing food safety hazards and breaches in food safety plans. The purpose of a CAP is to identify the root cause of a problem and establish steps to correct it. Here is an example of a Corrective Action Plan:

Let's say a restaurant has received a complaint from a customer who reported experiencing symptoms of a foodborne illness after eating a dish at the restaurant. This is a clear indication of a food safety breach and the restaurant must take immediate action to prevent further harm to its customers.

The first step in developing a CAP is to investigate the incident thoroughly. The restaurant's management team should interview the customer, review the menu items that the customer consumed, and inspect the kitchen and food preparation areas for any signs of contamination or other food safety hazards.

Once the root cause of the problem has been identified, the restaurant should establish critical limits for each of the identified hazards. For example, if it is determined that the food was not cooked to the appropriate temperature, the critical limit would be the minimum temperature required to kill harmful bacteria.

Next, the restaurant should implement corrective actions to address the issue. This could involve retraining kitchen staff on proper food preparation techniques, conducting regular food safety audits, or purchasing new equipment to prevent cross-contamination.

The final step is to monitor and verify that the corrective actions have been effective. This involves regularly testing food samples, inspecting food preparation areas, and reviewing employee training records. It is essential to ensure that the critical limits are being met consistently and that the corrective actions have been successful in preventing future food safety breaches.

In conclusion, a Corrective Action Plan is a vital component of any food safety program. It enables restaurants and food businesses to respond quickly and effectively to food safety hazards, prevent foodborne illness, and protect their customers' health. By identifying the root cause of the problem, establishing critical limits, implementing corrective actions, and monitoring and verifying the results, food businesses can ensure that their customers are safe and their reputations are protected.

How Inecta Can Help

In today's fast-paced food industry, it's essential to have an efficient system for creating and maintaining a corrective action plan (CAP). Inecta Food ERP is a comprehensive software solution that can help food businesses develop and manage their CAPs.

One of the key features of Inecta Food ERP is its ability to automate the CAP process. With this software, businesses can easily identify and track food safety hazards and breaches, establish critical limits, and implement corrective actions. The system can also monitor and verify the effectiveness of these actions, ensuring that the business is in compliance with all food safety regulations.

Inecta Food ERP also enables businesses to centralize their food safety data. All information related to food safety hazards, breaches, and corrective actions can be stored in a single, secure location, making it easy to access and analyze. This data can be used to identify patterns and trends, which can help businesses proactively address potential food safety issues before they occur.

Another benefit of Inecta Food ERP is that it helps to ensure employee compliance with food safety protocols. The system includes training modules that can be customized to meet the specific needs of each business. This training can be delivered online or in-person, and can be tracked and monitored to ensure that all employees are up-to-date on the latest food safety practices.

Finally, Inecta Food ERP provides businesses with real-time visibility into their food safety performance. The system can generate reports and dashboards that provide insights into critical metrics such as critical limit violations, corrective actions taken, and employee compliance rates. This visibility enables businesses to make informed decisions about their food safety programs, ensuring that they are effective and compliant with all regulations.

In conclusion, Inecta Food ERP is a powerful tool for food businesses looking to create and maintain a corrective action plan. Its automation capabilities, centralized data storage, employee training modules, and real-time visibility make it a valuable asset in managing food safety risks and ensuring compliance with all regulations. With Inecta Food ERP, businesses can focus on providing safe, high-quality food products to their customers, while minimizing their risk of food safety breaches and the associated costs and reputational damage.

.png?width=300&height=388&name=thumb+Hazard+Analysis+Template+v.2019.02.13+(1).png)

.png?width=300&height=388&name=Thumb+Process+Preventive+Controls+v.2019.02.13+(1).png)

.png?width=300&height=388&name=thumb+Corrective+Action+Template+v2019.02.13+(1).png)

.png?width=300&height=232&name=Receiving+Log+v.2019.02.13+(1).png)

.png?width=300&height=388&name=thumb+pH+Calibration+Log+(1).png)

.png?width=300&height=388&name=thumb+Pest+Sighting+Log+2019.02.13+(1).png)

Free Valuable Resource!

3 simple steps to find your Food ERP

Free Valuable Resource!

3 simple steps to find your Food ERP

*We will never sell your information. Keeping your data and privacy secure is our highest concern.