Global headquarters:

225 Broadway #660, New York, NY 10007

Canada Office:

21 King Street West, Ste 524 Hamilton, ON L8P 4W7

Take a look at additional functionality layered on top of our core software offering.

Broaden your ERP knowledge in more ways than one.

We know food and we have your industry covered.

Updated: November 24, 2025

inecta Food ERP unifies purchasing, production, inventory, quality, and finance in one system built specifically for food, so you can see what you have, where it is, what it’s worth, and how safely it moved—cutting waste, tightening margins, and making recalls and audits far less painful.

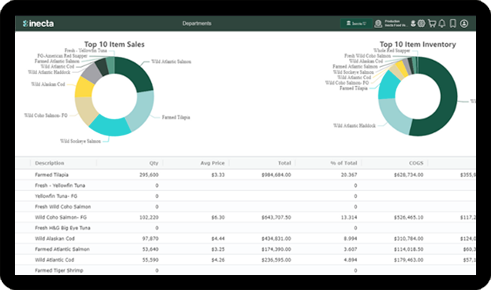

What sets inecta apart is that it’s food-only and micro-vertical by design (meat, seafood, produce, bakery, dairy, etc.), with out-of-the-box workflows for lot traceability, warehousing, catch weight, shelf life, processing/production, and compliance—rather than a generic ERP with a few food features bolted on.

inecta food manufacturing software includes many tools to help you plan, schedule and organize an efficient manufacturing pattern. With an integrated single hub, you can manage resources and materials to meet manufacturing demand without overstocking.

According to Food Allergy Research & Education, around 15 million Americans and one in 13 children has food allergies. Around 2/3 of all consumers say they follow a specialized diet, Inecta provides a rigorous framework to help manage ingredient tracking and tracing for food and beverage manufacturers.

With real-time tracking and a single hub in Inecta, you can set parameters for inspection of incoming goods & ingredients, work-in-progress and final products to ensure consistency and stringent product quality. Integrated recording and reporting means you are well-prepared for regulatory audits and mock recalls.

inecta food software helps companies navigate production complexity without getting overwhelmed in detail, by providing total visibility of the business, departments or functions. Improved material planning improves inventory accuracy, allowing you to streamline ordering to meet demand.

inecta's fully comprehensive ERP solutions for food and beverage industry will take your business to the next level with cutting-edge software designed for the digital age. With both on-premises and 100% Cloud-hosting capability, our Microsoft-powered solutions can help your company achieve its goals by streamlining virtually every facet of your business.

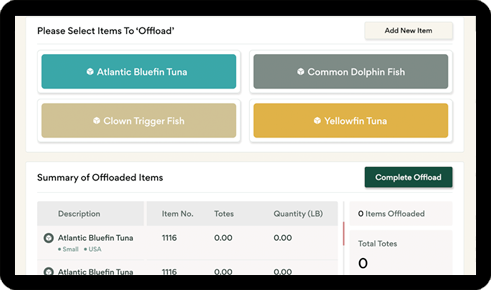

Using a mobile device you can now receive product into your warehouse or distribution center operations without the need for entering the data at a PC. Ensure accuracy and efficiency by getting the job done at the receiving dock.

When warehouse employees are moving product, you can use the handheld device to record supply chain movement in real time and keep your inventory and other users up-to-date on where product is located in your warehouse

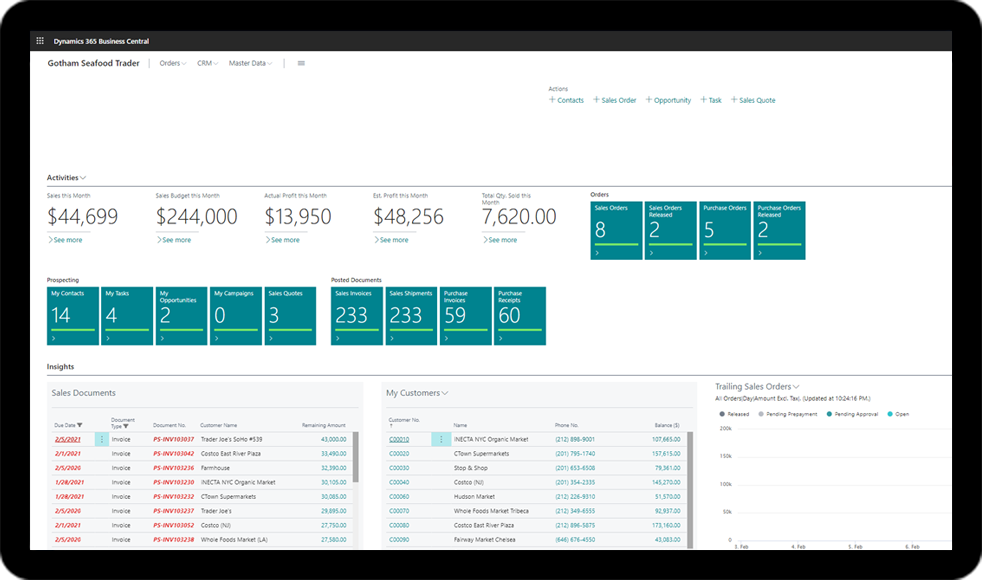

inecta Food is powered by Microsoft Business Central, the proven solution for comprehensive functionality & scalability to streamline operations, gain insights, and make informed business decisions.

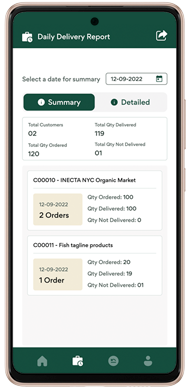

Empower your route drivers to manage deliveries and payment collection. Go paper-less and eliminate errors with your distribution business. With the easy-to-use app that's fully connected and synched to your Business Central system.

A clean, simple interface allows floor workers to easily enter information. Transform your food plant floor with advanced touchscreen software. Operational efficiency and precision right at your fingertips.

General business software isn’t designed to handle the complexities of food manufacturing. Purpose‑built food manufacturing ERPs manage perishable ingredients, track variable‑weight items, and enforce FEFO inventory protocols while embedding quality control and allergen tracking to meet FSMA and SQF requirements.

inecta’s food manufacturing ERP centralizes recipe management and production scheduling, capturing real‑time data on orders, materials and yields. Integrated supply‑chain and warehouse tools keep inventory accurate, while bidirectional lot traceability and margin analysis help ensure compliance and profitability.

All of our inecta Food and Beverage industry solutions are powered by Microsoft Dynamics 365 Business Central. This means that you have Microsoft's premier ERP solution powering your industry-specific operations 24/7.

Business Central works with one convenient database. BC allows you to seamlessly access data in real time, so you know exactly where your business stands at any given time. Business Central can also evolve to fit your needs, whether that means you require less or more funcionality, BC is in your corner every step of the way.

A mock product recall is designed to test the effectiveness of your procedures in the event of a real situation in which an ingredients or products are affected.

With Inecta Food, your team can track all ingredients, work-in-progress through to finished goods with an easy to use forward and backward traceability system that provides a complete visibility of the supply-chain in seconds.

Inecta offers a highly flexible track and trace system. You determine what lot attributes to set on all incoming goods: country of origin, supplier, brand name, production or expiry date, and more. The choice is up to you.

With inecta you can be confident that you have the measures in place to protect your

company and brand reputation in the event that a real food emergency happens to you.

Ask our team for a demonstration of Lot Traceability and get the assurance you need.

Jason Bellingham, owner of JBL Foods

%20(8).png)

.png)

%20(4).png)

%20(3).png)

inecta specializes in designing and engineering specific food and beverage industry software so you can get up and running fast. We work closely with food and beverage manufacturers, companies in seafood, and produce to create dedicated solutions for each sector, reducing the need for costly customizations out of the gate.

Our dedicated food and beverage team guides you through every phase—implementation, launch, and beyond—ensuring a seamless transition and ongoing success. We offer 24/7 support with emergency escalation (SLA) for critical issues and provide onsite assistance to address your needs directly.

Say good-bye to hardware woes and maintenance. Because inecta Food Software is managed in the cloud, we look after all software upgrades and releases automatically. As a Microsoft Gold Certified Partner, we receive and test any new releases two months ahead, allowing for a seamless transition to our customers.

Getting the assistance your business needs quickly is what inecta is all about. To that end, Inecta is equipped with highly trained professionals to field your support requests at the drop of a hat—anytime, anywhere. Whether by phone, email, or through Microsoft Teams, Inecta’s team of ERP consultants and developers are at the ready, waiting to help with any kind of query that arises.

Enjoy working with familiar MS office applications such as Microsoft Excel, Outlook, and Teams directly linked through your ERP software. Inecta can set up your own e-Commerce platform or link to a third-party provider such as Shopify. Connect to other applications without difficulties through open APIs.

Food ERP is ERP software designed specifically for food and beverage businesses. It still covers the usual ERP areas—purchasing, production, inventory, sales, finance—but adds food-industry features like recipe and batch management, catch-weight handling, lot and sub-lot traceability, expiration and shelf-life tracking, allergen management, and tools to support HACCP and food-safety programs. Generic ERP can track items and orders, but usually treats everything like a standard part number; it rarely understands perishable inventory, variable weights, or regulatory needs out of the box. inecta Food ERP, for instance, is built on Microsoft Dynamics 365 Business Central but adds industry-specific modules for seafood, meat, bakery, dairy, produce, and other verticals so day-to-day workflows match how food companies really operate.

Food ERP (Enterprise Resource Planning) Software takes into account and solves challenges that are unique to the Food Industry. An ERP that's specifically made for the Food Industry helps with maintaining food safety, tracing recalls, food manufacturing, food delivery, catch weight, grower accounting, and many more unique concerns.

Modern Food ERP systems are built to plug into the rest of your stack with standard connectors and APIs instead of one-off custom scripts. inecta Food ERP, for example, sits on Microsoft Dynamics 365 Business Central and offers modules for WMS, EDI, transportation, B2B portals, and integrations as part of the core platform, so warehouse scanning, carrier updates, and order flows can be configured rather than hard-coded. A good Food ERP will expose items, lots, orders, and inventory to your WMS and 3PLs; send and receive EDI documents with trading partners; feed labels and barcodes with the correct lot and allergen data; and sync orders and inventory with e-commerce—all while keeping a single source of truth in ERP. The goal is to centralize data in Food ERP and use standard integration tools for the edges, so upgrades don’t break everything each time.

Most mid-market food companies see ROI from a Food ERP in a few repeatable places: less product wasted, fewer chargebacks and compliance penalties, lower labor spent on firefighting and manual reconciliation, and tighter control of inventory and working capital. Industry examples show food ERP projects driving measurable reductions in scrap and write-offs through better shelf-life planning and FEFO picking, improved fill rates, and faster response to recalls and customer issues. inecta positions its Food ERP as a way to centralize operations—purchasing, production, warehouse, and finance—so you see your true costs and margins and can quickly attack the biggest leaks. Over a 5–7-year window, most of the return typically comes from: reduced waste and write-offs, lower overtime and emergency freight, fewer stockouts and lost sales, and less cash tied up in “just in case” inventory.

A good Food ERP should move the needle on all four. On margins, food-specific costing, yield tracking, and lot-level inventory help you see which products and customers are actually profitable so you can adjust pricing, promotions, or product mix. On waste, native expiration and shelf-life control, FEFO/ FIFO strategies, and better production planning reduce throw-aways and rework. On service, real-time inventory and production visibility support more reliable promise dates and on-time, in-full deliveries. And on recall readiness, inecta and other food ERPs provide bidirectional lot traceability and built-in recall procedures so you can identify affected raw materials, WIP, and finished goods and generate required documentation in seconds or minutes instead of days.

Food ERP ties planning, production orders, quality checks, and inventory into one live system, so the schedule is based on real capacity, real materials, and real demand—not guesses in a spreadsheet. inecta’s manufacturing and processing-floor tools, for example, centralize recipe management and production scheduling while capturing real-time data on orders, materials, and yields. That lets planners group runs to minimize allergen or flavor changeovers, see when ingredients or packaging will be short, and react quickly when lines slow down. Floor staff can record actual weights, yields, and variances directly in the system, which reduces rework and “surprises” at month-end. Over time, this feedback loop tightens schedule adherence and cuts down on last-minute expediting and firefighting.

In a Food ERP, every receipt, internal movement, production step, and shipment is tied to lot numbers, so you can trace a raw lot from supplier, through batches and rework, all the way to finished goods and customers—and back again from a consumer complaint to the original ingredients. inecta highlights “bidirectional lot traceability” and recall functionality that can show affected ingredients, WIP, and finished goods and help you isolate risky inventory quickly. For shelf-life and FEFO, Food ERP tracks expiration at the lot level, enforces first-to-expire picking and replenishment, and can block or warn on short-dated inventory, which is standard practice in modern F&B ERPs. Mock recalls then become a report and workflow inside the system: you select a suspect lot, the ERP shows every batch and customer it touched, and you can document actions taken for regulators and customers.

Because a Food ERP connects recipes, production orders, yields, inventory, and sales, it can calculate the real cost of each batch—including ingredients, labor, packaging, overhead, and sometimes energy or freight—and then roll those costs to SKUs and shipments. Solutions like inecta track recipes and yields, support batch-aware inventory, and tie everything back to financials, which enables margin analysis at different levels: item, customer, channel, or even specific campaigns. Co-products and byproducts can be modeled as additional outputs of a batch with their own cost allocation rules, so you see which lines and products are helping or hurting your overall margin, instead of guessing from averages.

Practically, waste reduction comes from better visibility and better rules. Food ERPs track expiration dates and storage conditions at the lot level, apply FEFO or FIFO automatically, and warn when products are about to expire so you can use, rework, or discount them before they become a loss. They also tighten quality workflows, so non-conforming lots are put on hold, inspected, and either released, reworked, or scrapped with full documentation. inecta’s traceability and QC features, for example, are designed to identify risky lots and unsafe production stages early, reducing the chance that bad product makes it to customers or sits unseen in a freezer until it expires. Better planning and accurate inventory also mean you buy and produce closer to real demand, which cuts overproduction and giveaway at the source.

Food ERP systems typically let you define quality checkpoints, critical control points (CCPs), and inspection plans that are embedded into receiving, production, and shipping processes. During operations, staff record temperatures, weights, test results, and sign-offs directly in the system; non-conformances can automatically put lots on hold and trigger investigation or rework. inecta’s food ERP solutions emphasize compliance and traceability, with features to support food-safety standards, labeling rules, and documentation so you can show exactly what was done, when, and by whom during an audit. Because financial transactions (purchasing, production postings, inventory adjustments, invoicing) are in the same system, you also get audit trails for costs, quantities, and approvals, which helps both food-safety inspectors and financial auditors follow the chain of events.

Most mid-market Food ERP projects run several months to under a year, depending on scope, number of sites, data cleanup, and integrations. Industry guidance suggests that focused “phase 1” rollouts—traceability, QC, FEFO, core WMS, and basic planning—can go live faster than big-bang implementations that attempt advanced planning and complex multi-site setups on day one. The main risks are poor data preparation, unclear processes, underestimating change management on the plant floor, and over-customizing instead of using standard food-industry capabilities. When choosing a vendor, food manufacturers are usually best served by: (1) a platform they trust—like Microsoft Dynamics 365 Business Central—and (2) a partner with deep food vertical experience, industry templates, and proven solutions for their specific segments (seafood, meat, produce, bakery, etc.). inecta positions itself exactly this way: a food-first ERP suite on Business Central with industry-specific modules and long experience in food manufacturing, distribution, seafood, and produce.

225 Broadway #660, New York, NY 10007

21 King Street West, Ste 524 Hamilton, ON L8P 4W7

© 2026 inecta LLC. All rights reserved.